I've decided to repeat the first and last portions for every Leader-Led post I write.

Over the years that I have been leading myself (and others) on the journey to a culture of continuous improvement, I've learned that the most important thing is the leaders are the first followers. That means that; they implement the tools in their own areas before expecting others to do it, a.k.a. walk the talk.

For my third entry, I am going to talk about Standard Work for Leaders and LSW. These are two different tools that people constantly get mixed up. Often, they think that Standard (or Standardized) Work is something that operators or mechanics do, while management and leadership uses LSW. This is not the case. Standardized Work for Leaders is very much like Standardized Work for operators and mechanics. The only difference is (much like with all visual controls) the amount and intensity of visuals should be directly correlated to how many people and how often the tasks are done. If you have a meeting daily with the entire team, you need to be more specific about what information and actions people should provide. If you have a meeting once a month between two people, that still should have a general agenda but can flex with content.

This is why LSW is one of the most mis-used tools, because it is a sum of parts. Essentially it breaks down into: Standardized Work (typically for the management system), Coaching the Standardized Work (this is another large topic I will get into later), and To-Do tasks that come from the Standardized Work/Coaching. There is a lot of work behind that simplicity, which is why people often try and fail at LSW, often without even knowing they did.

You do not need to have Standardized Work, nor Coaching, to start doing LSW. However it will be very difficult (if not impossible) to get all the benefits typically associated with LSW. Using the same example from earlier, it will be difficult to coach and measure the effectiveness of a Tiered Meeting without Standardized Work for it (typically in the form of an Agenda and whiteboard with KPIs or Leading Indicators on it).

In this post, I'm going to share how to implement and use LSW as a Lean Professional (or a leader who wants to use the tool to set the example). I will start with us, because Leader-Led is the title of this series.

First, write down the Standardized/Structured tasks you do on a reoccurring basis for the management system. E.x. Tiered Meetings, Hoshin Kanri, GEMBA walks, 5S, Kanban, etc. If you don't have those tools yet, you should start writing down implementation steps as milestones on your Hoshin Kanri Strategy.

As you are part of a support groups and/or management, there are layers of non-value added..ness to your tasks, if you will. Coaching against a standard way to make a product is as close as a leader will ever get to doing it themselves. Coaching that management system is one step removed, but still important. This gets a little META, and yes I mean that in the literary sense, but stay with me here. Having a formalized process coaching for those standards and the management system that support them will improve the fit/form/function of the product and make it cost less to make. Again, we will get into the Coaching tool in-depth on a later post, but a quick rule of thumb is to coach the tools in one schedule step up from when they occur. E.x. if the GEMBA walks happen 3x/day, you coach them 3x/wk and if Tier 1 meetings occur daily, you coach 1x/wk.

So you now wrote down your standardized work, congratulations, it is a step that is actually more difficult than many people think. Again, if these do not have standards and/or do not exist, you really should start helping to develop them as part of your Hoshin Kanri Strategy planning.

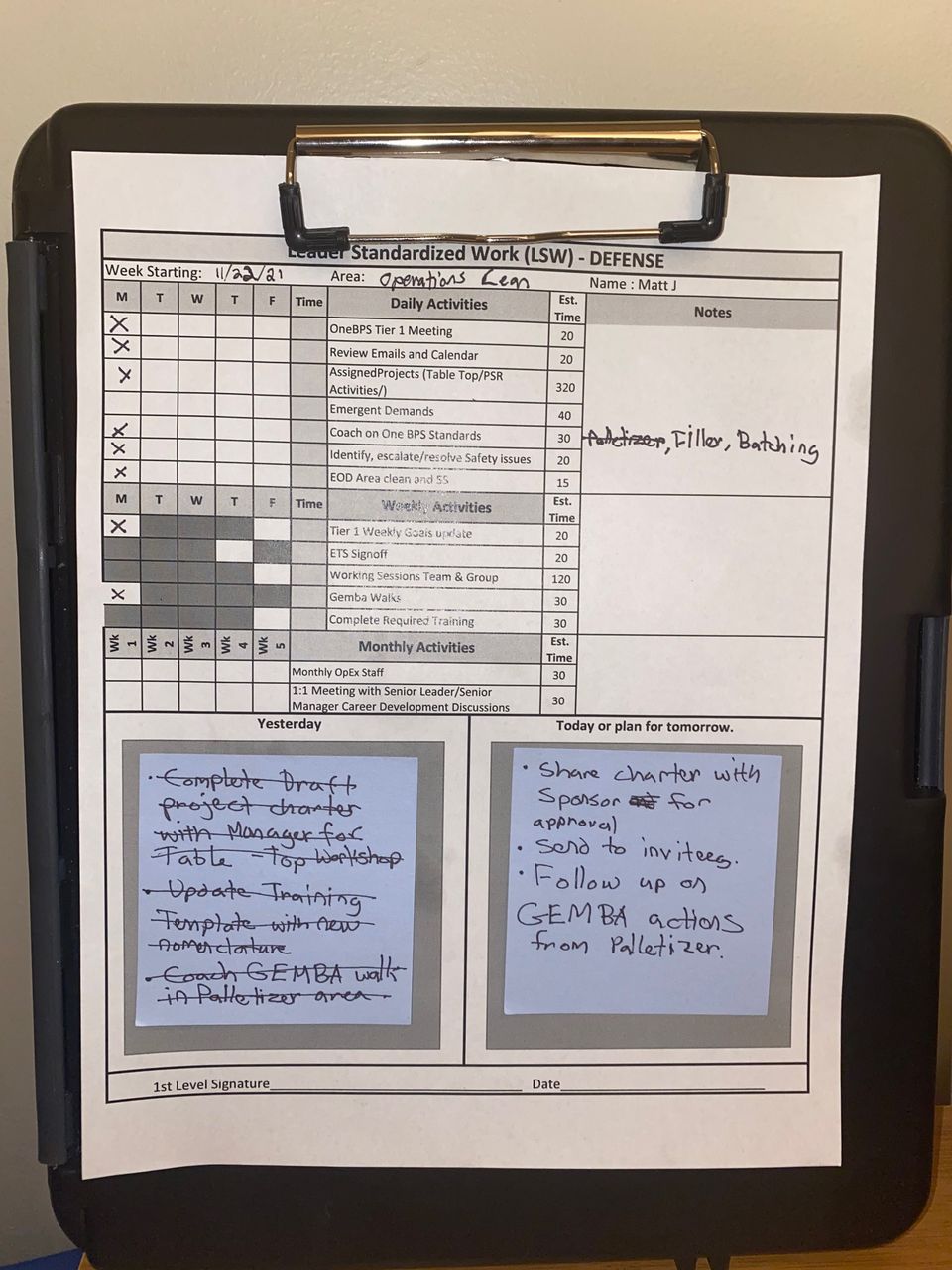

Now you take these and put in a weekly calendar format, there are dozens of LSW templates floating around the internet you can download and tweak to your liking.*

*Pro-tip: I've had LSW exist as a daily form, a weekly form, even a monthly PowerPoint. We ended up reviewing weekly no matter what format we started with. It is probably the best balance to keep focused while not tripping up.

The last step is to put space for sticky notes, one for today and one for tomorrow. These are the tasks you set as goals during your daily tiered meeting. Support groups typically should have a milestone or SCRUM-style board utilized as the "Delivery" or "Performance" part of their Tiered Meeting Board (SQPD visual board). Your sticky notes should be aligned with those, and your weekly goals should be aligned with Hoshin Kanri. E.x. if your Hoshin Kanri includes "stabilize efficiency between operators to +/- 5% of gold standard changeover time by implementing and coaching standardized work", you should have milestones on your SQPD board that shows the path of implementation, e.x. "determine pilot area, train operators & leadership on standardized work, write standardized work, perform change management process, train and sign-off operators, setup and maintain coaching schedule, determine next area"...repeat. You should be writing on your sticky notes "meeting with director to determine pilot area, train managers, train 1st shift, train 2nd shift, etc". You cross these things off as you complete them on the sticky note(s), share and cross off on your Tiered SQPD board, then cross the higher-level milestones off as they are completed. Anything that does not get done on time should be discussed and actioned, as with any Tiered Meeting.

Finally, setup weekly coaching (can also call them reflections) about your LSW with your manager. Think about what went well, what could go better, and what either (or both) of you can do about one of the things that could have gone better. The focus should be around efficiently using your time. If you need help with things that could have gone better, think about the 7 wastes that popped up during your work last week. Did you have to re-train someone on a tool they used improperly? What could be different about the process and/or how you presented to avoid this? What are your managers thoughts? You can thus use this tool to help efficiently use your time, making it better going forward. LSW is, after all, ultimately a time management tool.

Take this, and tweak it as you go. As with all of the tools, make it so it benefits you, but don’t stray from the intent. Your goal is to maximize your effectiveness, just like your goal is to maximize the effectiveness of the people that work with you.

Just like the other posts, the last section is also worth repeating.

This sets you up for success when implementing LSW. If you are a CI leader (CI mgr, Lean practitioner, OpEx Lead, etc.), that means yours should be done before the first training. Then when you start training people, you can bring them to your area as a LSW GEMBA walk. Then they can start implementing in their own areas and train others based upon actually doing to themselves first.

This, everyone, is simple and invaluable to an organizations Continuous Improvement culture. As with all CI/Lean things, I cannot guarantee this will give success, but without it I can 99.99999% guarantee failure.

Thanks for your time,

Lean Matt