The first paragraph of my previous post is important to repeat...

Over the years that I have been leading myself (and others) on the journey to a culture of continuous improvement, I've learned that the most important thing is the leaders are the first followers. That means that; they implement the tools in their own areas before expecting others to do it, a.k.a. walk the talk.

My second entry in these posts is implementing Kanban in an office environment. As with most Continuous Improvement tools, it is tied into visual controls and 5S, although this is focused on using those to maintain & sustain inventory levels at the proper amount. As a leader, you should be doing this for your office materials to demonstrate inventory amounts and sticking to behaviors that maintain them.

When I say proper amount, people usually think of lean means the minimum amount. The "toss everything" seems to follow us from 5S to Kanban...and honestly every tool associated with lean. Even the name means that. Yes, from the outside this seems like the case, however a true lean Kanban means trying to reduce the time before the set amount (whatever that set amount is) can be refilled. This keeps inventory levels low by being as pull-based as possible. Think of single-piece flow and how it is quicker than batch. If you can try to align customer demand the same way, it also will be more efficient, because true Lean Manufacturing supports it.

As with 5S, the amount of visual controls should be be directly proportional to how frequently it is used and by how many different people. Kanban should strive to minimize the amount of signage, travel, and time from an out-of stock situation to an in-stock situation.

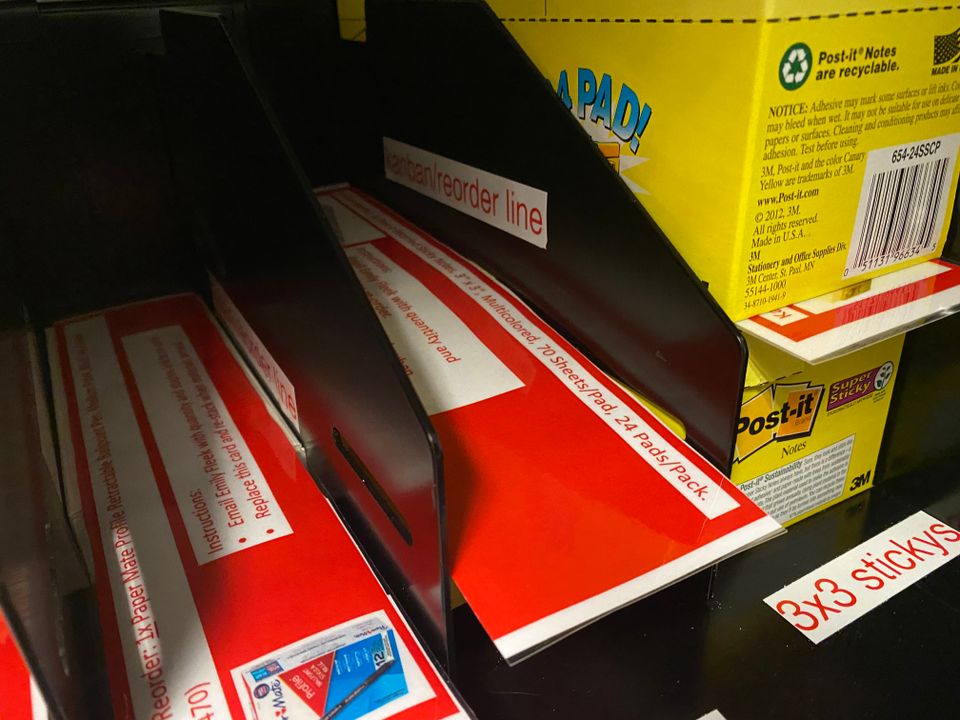

To demonstrate leader-led kanban, I would 5S the office materials first with input from others. Literally follow the same steps, except add in red kanban cards during the 4th S (Standardize). Try to keep size in mind. E.x. if you have 3"x3" stickie notes (like most lean people have in abundance), look at the size of the box/container you want as an Minimum Order Quantity (MOQ). Take the dimensions from Staples (or whever you order from) and make a slot & cutout to store it. As always with first drafts, simpler is better. Leftover paper boxes, duct tape, whatever you have for your drawers and/or shelves.

*Pro-tip: You should definitely use dividers, even if they are cardboard. This keeps stuff from tipping over.

The final step is much like the 5th S (Standardize). You make min and max lines based upon estimates from people tthat work in the area. You make a simple standardized work and post it in the area. This standaridzed work should include a process map. The process should be something like:

1. If you take the last of something on top of the kanban card. 2. Take the kanban card and reorder. 3. Contact (information) for reorder and item number from Staples (or whever). 4. Hold onto the kanban card until materials arrive. 5. Place the newly arrived box and re-stack so the box already in-use is on top and kanban card is @ line. 6. If you run out quicker than replenishment, or go above the max level, notify your 5S champion (contact info).

*Another pro-tip: You can implement a simple count system for more expensive items frequently used, such as label tape. However, I would wait until the first round of kanbans, because you may not actually need that much at therefore it will become less expensive per year to order.

The last two paragraphs of my previous post are also worth wile to repeat...

This sets you up for success when implementing Kanban. If you are a CI leader (CI mgr, Lean practitioner, OpEx Lead, etc.), that means yours should be done before the first training. Then when you start training people, you can bring them to your area as a Kanban GEMBA walk. Then they can start implementing in their own areas and train others based upon actually doing to themselves first.

This, everyone, is simple and invaluable to an organizations Continuous Improvement culture. As with all CI/Lean things, I cannot guarantee this will give success, but without it I can 99.99999% guarantee failure.

Thanks for your time,

Lean Matt